It is 6 a.m. on an average Wednesday morning in the United States. At this time, millions of Americans are placing a K-Cup into a Keurig, coffee grounds into a coffee maker or running to a local coffee chain for an extra dose of caffeine to get them through their morning.

https://www.youtube.com/watch?v=Ywt1e2u5D3Y&feature=youtu.be

Meanwhile, in Central America, a number of farmers such as Carlos have been awake for over an hour. By 6:30 a.m., he is already making his way down a dusty mountain range in San Lucas, Guatemala, carrying a heavy sack of coffee cherries on his back. Then, he heads to his job at Juan Ana Cafe in his home of San Lucas, to help harvest, process and market the coffee that he makes by hand. During this time of year, Carlos prepares for the months of the coffee harvest season by caring for coffee plants and the land that they grow on to sustain the lives of his people.

These coffee plants produce the $40 billion that the United States spends on coffee each year. The hands of hardworking individuals like Carlos are who we can thank for processing 600,000 pounds of picked coffee beans each year to make the hot, addicting cup of caffeine that most of us rely on to start each and every day.

The whole process — from the coffee plant, to the dehusking, roasting, grinding and packaging of the finished product — are done by faces that we may never be able to see and people we will never get to know in this lifetime. However, that does not give us a reason to be ignorant or unappreciative.

From the bean to your cup

Harvesting

Coffee harvesting takes place between November and February. Carlos ventures out onto his land in San Lucas, sometimes for as long as seven hours a day, to pick around 150 to 200 pounds of coffee by hand. For Carlos, harvesting coffee is not a daily chore, or just a days’ or weeks’ work. This process is part of his culture, similar to how Americans sit down to share a Sunday evening meal or spend time with extended family on a holiday. The labor intensive work of converting the red bean into a beverage is just beginning, though.

After Carlos picks the red-bean coffee, he must treat and wash it that same day. In order to do this, he usually works at the “beneficio” past midnight. The coffee is first de-pulped to remove the bean from the red shell. This is done by a machine, but Carlos must monitor the machine while it is being done. The coffee bean is then left to soak in large tubs, washed over two or three days to remove a honey coating, and then put out in the sun to dry.

Following 8-10 days of drying, supervision and raking by the hour, beige pergamino coffee beans remain. Pergamino coffee is a dry coffee bean enclosed in a dry, beige shell.

Washing, drying and humidity

On an average day, Carlos officially begins the process of coffee production by checking the pergamino coffee’s level of humidity. Coffee has to be kept at a certain humidity level, and farmers use absorbing bags to store coffee at that right level.

Experienced farmers such as Carlos can detect the level of humidity just by looking at coffee, or by using a special humidity level machine. If the level is more than 15 percent, it is considered very humid. If the beans are too dry, they are less than 10 percent humidity. It is difficult to dehusk beans at a high humidity level because the beans still have the husk and are very hard and humid.

Dehusking

Carlos then takes the pergamino coffee of proper humidity and processes those beans through a dehusking machine for about one minute to remove the shells. After a minute, he clears any remaining husk or broken means that may still be mixed in. What remains is a green bean. This bean is what is later roasted to becomes the product that we are buy off of supermarket shelves.

Selection

The all important roasting process happens at the hands of well trained locals, such as Carlos, who have taken classes on how to properly roast coffee beans. He is knowledgeable enough to manually select beans in order to maintain the quality of the product.

During this process, Carlos must pay close attention to ensure that small or broken beans are not picked to be roasted. If bad beans are roasted with good beans, the small and broken beans will burn when the regular beans are just reaching the point of being roasted. This results in a very low quality and low value roast.

Roasting

After all of the coffee has been checked for humidity, dehusked and manually selected by hand, there should only be green coffee beans left. Then, the roasting process can begin. Carlos starts by lighting the roasting machine. The heat and length of the roast are what draws out the different distinct aromas and flavors of coffee. The coffee takes about 10 to 12 minutes to roast with changes of the color of the coffee beans along the way.

When the machine reaches 300 degrees Fahrenheit, the green coffee is put into the machine for a dehydration process that takes about six to seven minutes. When the coffee reaches its point of dehydration and no longer has any more humidity left in it, it will then turn yellow. From that point onward, the changes in the color of the bean occur very rapidly.

When the coffee is almost at the point of being roasted, a sound similar to what we know as popcorn popping will indicate that it is almost finished. An average roasting time is usually about 10 minutes and 50 seconds. When the process is finished, it is necessary to wait a few minutes for the beans to cool.

Carlos must watch the time and temperature of this process very carefully to ensure that it will result in a good quality roast. Farmers cannot roast coffee for a shorter time at a higher temperature, or for a longer time at a lower temperature, because that would not result in a quality roast or taste.

A Dark Roast is roasted longer and at a higher temperature, resulting in a signature bold taste. The Regular (Medium) Roast is roasted shorter and at a lower temperature, creating a flavorful taste with a smooth finish.

Every single step of this process must be done carefully to account for the rich flavor that most of us enjoy in our coffee each and every morning.

Shipping

At Juan Ana Cafe, each and every bag of coffee is sewn and hand stamped with care by people like Carlos.

The coffee is placed in a mylar bag, vacuum sealed to keep the product fresh, then placed inside a cloth bag. The outer cloth bag is hand tied and then ready for export.

From a place like Juan Ana Cafe, exports of coffee are sent to the United States at as many as 4,000 lbs, or 70 boxes, per shipment. The boxes typically weigh 50 lbs each.

The hands and the heat

While Americans can afford to live without coffee, farmers like Carlos, who make a living by producing it cannot. Farming and producing coffee beans are how Carlos and many people in other parts of the world make an income to provide for themselves and their families.

However, if individuals in the United States continue to make careless decisions that contribute to the effects of climate change, poor and vulnerable farmers, their loved ones and communities will all suffer.

According to the National Aeronautics and Space Administration, the current warming trend of the Earth’s climate has a 95 percent probability of being the result of human activity. This warming trend will continue to proceed at a groundbreaking rate over the decades to come.

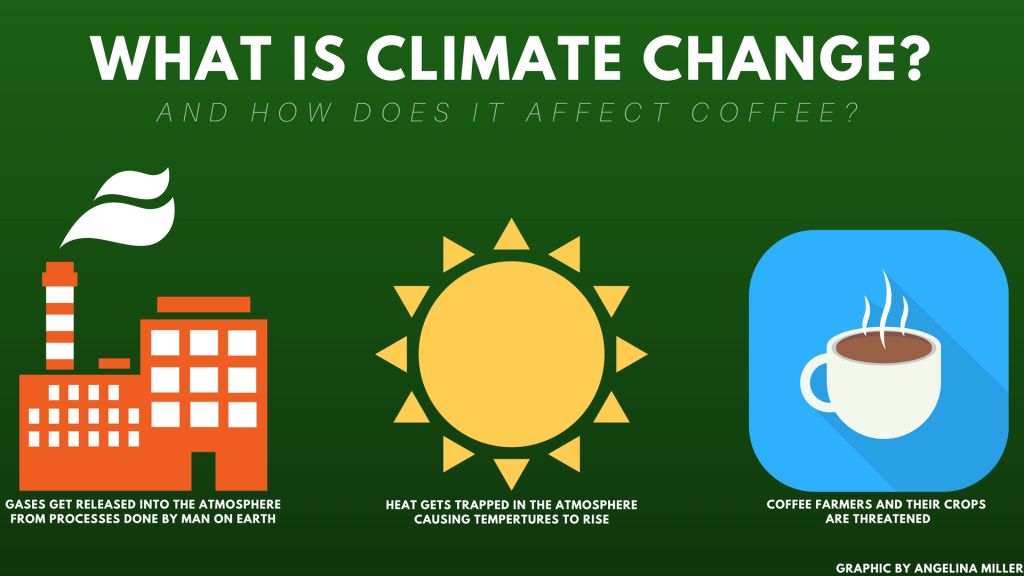

This all stems from what is known as the “Greenhouse Effect.” When carbon dioxide, methane and other gases are released from man made processes on Earth, heat gets trapped in the atmosphere. Scientific research today goes to show that having increased levels of greenhouse gases is unquestionably what causes the Earth to warm. As temperatures continue to warm, coffee farmers and their crops are threatened. This is specifically shown in terms of altitude and coffee leaf rust. Coffee leaf rust is a fungus that reproduces and attacks coffee plants with at a very specific temperature range of 64–73 degrees Fahrenheit.

If Carlos grows his coffee lower in altitude, he will have warmer temperatures, specifically at night. In these warmer areas, coffee rust has been a problem for 20 or 30 years now. However, with temperatures consecutively warmer at night and colder during the day, coffee leaf rust has begun to attack coffee plants all of the time.

Carlos is forced to keep moving up the mountains where he grows his coffee. However, mountains eventually reach a point where nothing can grow anymore. If Carlos gets to this point in the near future, he may be unable to grow the coffee that he needs for an income to live. Coffee leaf rust is not only moving from farm to farm but more so from community to community and even across the countries. The problem is not going away and neither are the struggles with the climate.

Starting a day by climbing up a mountain is no longer the only battle for Carlos anymore though. Fighting against climate change is the new day to day struggle that he and many others are facing. While he may have some control over his own farm, he has no control of our actions in the United States that will shape his future.